- #Servo motor arduino model solidworks how to#

- #Servo motor arduino model solidworks serial#

- #Servo motor arduino model solidworks driver#

- #Servo motor arduino model solidworks software#

- #Servo motor arduino model solidworks download#

The sensor reads 3 different values for each skittle, Red, Green and Blue and according to these values we tell what the actual color is. Using the four control pins and the frequency output pin of the color sensor we read color of the skittle. Next, after half a second delay, using the custom made function, readColor() we will read the color of the skittle.

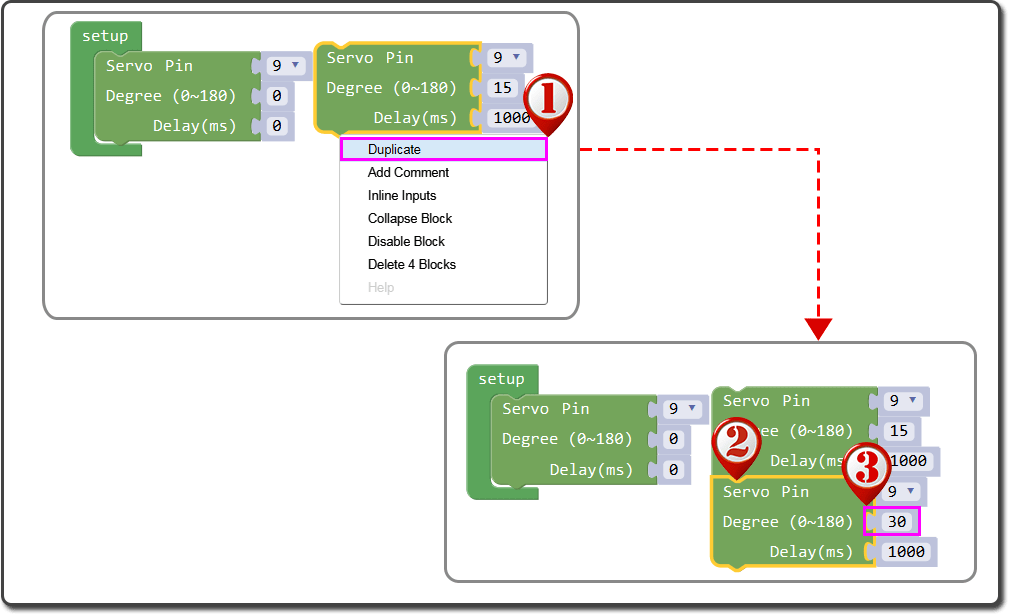

We are using a “for” loop so that we can control the speed of the rotation by changing the delay time in loop. Next using the “for” loop we will rotate and bring the skittle to the position of the color sensor. Note that this value of 115 suits to my parts and my servo motor, so you should adjust this value as well as the following values for the servo motors according to your build. In the loop section, our program starts with moving the top servo motor to the position of the skittle charger. With a number of different built in motor drivers, several easy connectors for.

#Servo motor arduino model solidworks serial#

In the setup section we need to define the pins as Outputs and Inputs, set the frequency-scaling for the color sensor, define the servo pins and start the serial communication for printing the results of the color read on the serial monitor. The MKR Motor Carrier makes it easy to control servo, DC and stepper motors. So, we need to include the “Servo.h” library, define the pins to which the color sensor will be connected, create the servo objects and declare some variables needed for the program. Setting frequency-scaling to 20% digitalWrite(S0, HIGH) */ # include # define S0 2 # define S1 3 # define S2 4 # define S3 5 # define sensorOut 6 Servo topServo

But if it is only 5 volts then it really is at a very marginal level./* Arduino Project - Color Sorting Machine all the components in Solidworks, using images and other 3D models as reference. Continuous rotation servos allow the rotation of the shaft to be set to various speeds. Each eye can be raised and lowered independently with servo motors. Standard servos allow the shaft to be positioned at various angles, usually between 0 and 180 degrees.

#Servo motor arduino model solidworks how to#

Servos have integrated gears and a shaft that can be precisely controlled. Showing the use of calipers and how to use these measurements to make a 3D CAD model that can be moved or even animated. If you had a somewhat higher voltage supply, at least 6 volts, then it would be ok. This library allows an Arduino board to control RC (hobby) servo motors. You are better off to not connect the servo power through the Uno board. With a 5 volt output of your external power supply, a voltage drop from the diode would give the servo almost enough voltage to meet the 4.8 volt minimum but not quite. The problem is that the servo voltage range 4.8 volts on the low end. This could provide a power path for the servo. After the glue has set, connect the pinion gear to the motor on the body. I used duct tape here.Then make a pinion gear by attaching two layers of gear parts with a motor part (the servo horn that came with the motor package). You can use either hot glue or duct tape.

#Servo motor arduino model solidworks software#

The Sparkfun schematic shows a diode in line with the barrel connector and the Vin connection point on the board. I am work with many types of software like a SolidWorks, AutoCAD, AutoDESK INVENTOR, FUSION 360, and 3D printing software. First, attach a servo motor on the body part (part 1). There is a voltage comparator circuit that will switch over to the barrel jack power if the voltage is high enough.īut since you are not really asking about powering the Uno, just the servo, then it gets interesting. 5 volts is too low if you plan on powering the Uno board with the external power source. Discover all CAD files of the DC servo motors category from Supplier-Certified Catalogs SOLIDWORKS, Inventor, Creo, CATIA, Solid Edge, autoCAD. If you want to use the barrel jack on the left, please note the listed input voltage. You did not indicate how you plan to connect the 5V, 2A mains plug pack to the Arduino board. As a bonus, CAD models of the nine gram servos were readily available in order to generate models of each arm segment to be 3D printed. The Redboard has a current limit of = 7v.

I'm going with the assumption that your "Arduino" is the Sparkfun Redboard. They can be use to create a steering mechanism for 4 wheeled robots.

#Servo motor arduino model solidworks download#

We simply plug it in the Arduino Board and control it with servo library. Model available for download in SolidWorks format.

#Servo motor arduino model solidworks driver#

They don't require any external motor driver components. Your question is not very concise, but I'll try to hit the main points. Servo motors are the easiest to control as they already have an integrated board within.

0 kommentar(er)

0 kommentar(er)